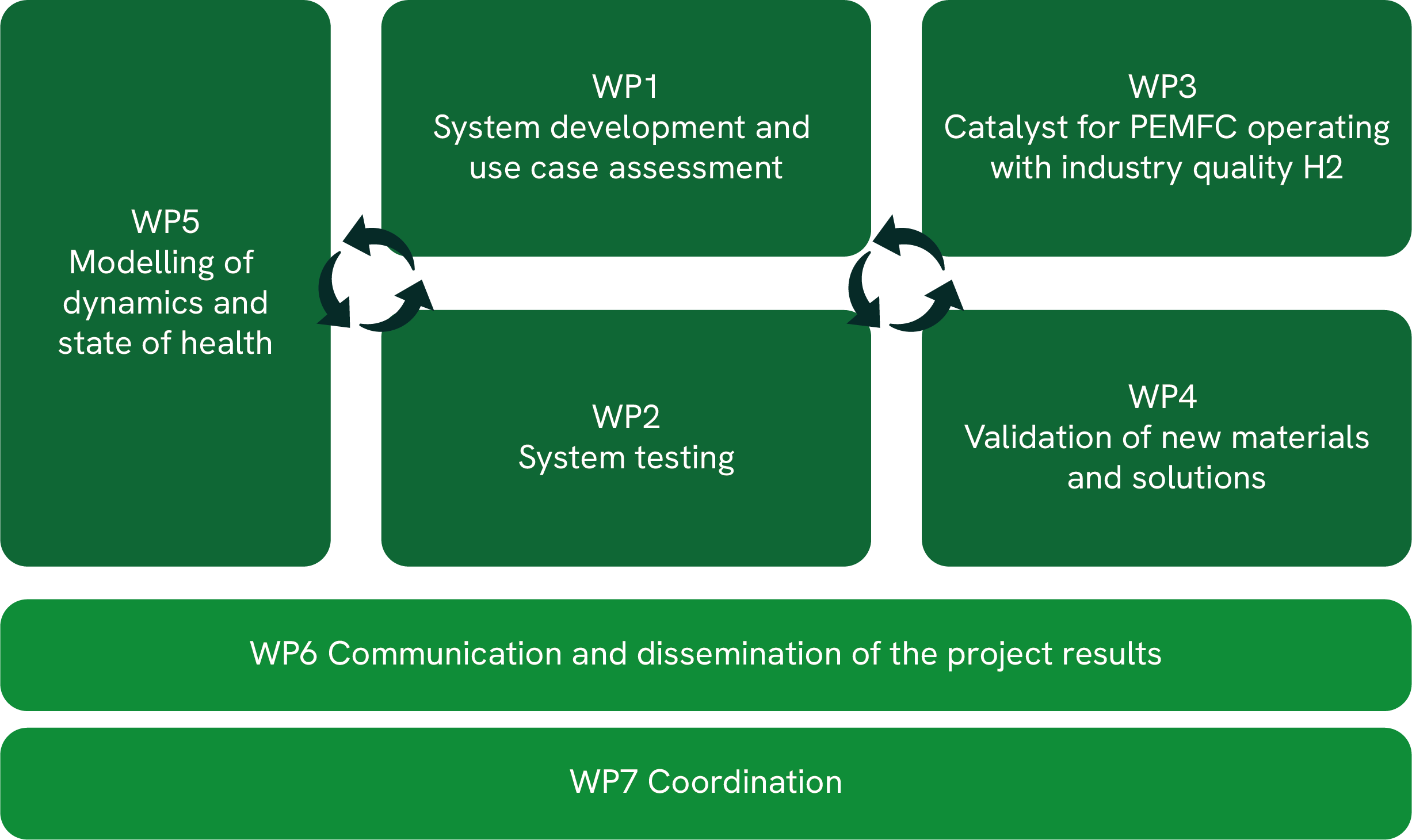

PROJECT STRUCTURE

CLEANER comprises 7 work packages: of which WP6 and WP7 provide support for the other core technical packages WP1, WP2, WP3, WP4 and WP5. The relationships between WPs are illustrated in the above below.

WORKPACKAGES DESCRIPTION

WP1: System and use case assessments aims to develop a 100 kW PEMFC system able to operate on industrial quality dry hydrogen. WP1 will also conduct techno-economic and environmental assessment regarding using the developed technology in selected case studies.

WP2: In the work package 2, methodology for testing fuel cell system level performance and durability is developed and validated at VTT. The developed method is used to validate performance of a 1st generation fuel cell system delivered by PowerCell using pure and low-grade hydrogen. 2nd generation fuel cell system is developed by PowerCell based on the test results. The new system will be tested at VTT with impure hydrogen up to total of 4500 hours in durability tests.

WP3: In WP3 (Catalysts for PEMFC operating with industrial H2), the group of Inorganic Functional Materials and Nanomaterials at the University of Freiburg will develop porous carbon catalyst supports and thereof derived electrocatalysts exhibiting enhanced stability at the cathode, improved tolerance against contaminations at the anode, as well as reduced PGM contents on both sides. Moreover, material strategies for advanced diagnostics will give new insights into fuel cell degradation processes. These advancements are expected to significantly extend the lifetime and efficiency of stationary PEM fuel cell systems being operated on industrial-grade hydrogen while at the same time reducing the cost of catalyst.

WP4: The main aim of WP4 is to validate the novel materials and solutions developed in the project on the single cell and short stack level, whilst using a realistic industrial quality hydrogen.

The first step will be to identify the type and concentration of contaminants that can be introduced into hydrogen from relevant storage and transmission solutions. The impact of these on fuel cell performance, and especially their accumulation in the anode recirculation loop during dead-end operation will be quantified. In addition, strategies for the mitigation of reversible performance loss associated with the use of industrial H2 will be developed and validated. The novel catalyst and support materials developed in the project will be compared to commercial baselines to determine their impurity tolerance and amenability to impurity mitigation strategies e.g. potential cycling.

Together, this will aid decision-making for the system testing in WP2, by providing recommendations such as improved materials and operation strategies for increased hydrogen utilisation whilst maintaining system performance and lifetime.

WP5: The WP5 will focus on system modelling, analyzing the dynamic behaviour and system reaction to contaminants. Furthermore, a data-driven approachwill be employed for the degradation model of the fuel cell, and a diagnostic capability will be added to the dynamic model.

WP6: The Knowledge Management, Communication and Dissemination WP involves all partners and is led by PRETEXO. It includes the sharing of project knowledge through a knowledge management protocols, and measures to exploit the project results through the updating and implementation of the draft exploitation plan. Communication and dissemination activities will include, a dedicated website, publications and conference presentations as well as newsletters and participation in JU Programme Review Days.